Why Does High-Quality Novel Book Printing Matter for Today’s Publishers?

2025-12-04

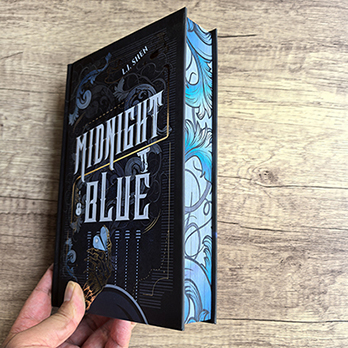

Novel book printing is the foundation that shapes how readers perceive a story long before they reach the first chapter. Paper quality, binding type, color accuracy, and printing precision all influence durability, readability, and emotional impact. For publishers, authors, and printing suppliers, the goal is to deliver a product that not only showcases the narrative but also meets market expectations for craftsmanship, consistency, and sustainability.

How Do Technical Specifications Influence Novel Book Printing Quality?

To produce a commercially competitive novel, technical accuracy and material selection play a crucial role. Every parameter—from paper thickness to binding type—affects production cost, reader comfort, shelf life, and brand positioning.

Key Novel Book Printing Parameters

| Category | Specification | Description |

|---|---|---|

| Paper Type | Offset Paper / Wood-free Paper / Recycled Paper | Determines texture, opacity, and ink absorption for long-form reading. |

| Paper Weight | 60gsm – 120gsm | Lighter weight reduces cost; heavier weight increases durability and opacity. |

| Cover Material | 250gsm–350gsm Coated Paper / Soft Touch / Matte / Glossy | Defines first impression, color vibrancy, and resistance to wear. |

| Cover Lamination | Matte, Gloss, Soft-Touch, Anti-Scratch | Adds protection and enhances tactile experience. |

| Trim Size | 5" x 8" / 6" x 9" / Custom Sizes | Standard sizes favored by the publishing market for novels. |

| Binding | Perfect Binding, Saddle Stitching, Hardcover Case Binding | Impacts durability and spine flexibility. |

| Printing Method | Offset CMYK / Digital / Spot Color | Determines color accuracy, ink density, and scalability. |

| Finishing Options | Foil Stamping, Embossing, Debossing, UV Coating | Adds premium appeal for brand differentiation. |

| Color Accuracy | Delta-E Color Control / ICC Color Profiles | Ensures consistent visual output across batches. |

These parameters allow manufacturers to ensure each novel meets publishers' expectations for durability, color fidelity, and tactile quality.

How Does Novel Book Printing Achieve Precision, Efficiency, and Market Competitiveness?

Novel printing involves more than simply placing ink on paper. It requires a coordinated workflow rooted in precision engineering, materials science, and production management. The following sections analyze how each process contributes to final quality.

How Does Material Selection Influence the Reading Experience?

Selecting the right paper determines how comfortably a reader can enjoy a story over several hours. Lightweight paper improves portability but may result in transparency between pages. Heavier paper reduces show-through and improves ink performance but increases shipping costs.

Cover materials also influence shelf appeal. A matte lamination creates a soft, elegant feel, while gloss lamination intensifies color saturation—ideal for commercial fiction covers.

How Does Offset Printing Deliver High Accuracy for Large-Volume Novels?

Offset printing remains the leading method for novel production due to several technical advantages:

-

Superior ink density control

-

Uniform color distribution across thousands of sheets

-

Cost-efficiency for medium to large print runs

-

Sharper text clarity, essential for novel readability

Through precise plate calibration and automated ink-flow control, offset production ensures every page maintains consistent tone density.

How Does Book Binding Impact Durability and Usability?

A novel may be read dozens of times, so binding is crucial.

Perfect Binding

Most common for softcover novels. Hot glue adheres the pages to the spine, providing a balanced combination of cost efficiency and durability.

Sewn Perfect Binding

Ideal for premium novels requiring longer lifespan. Sewing before gluing increases page stability and prevents page detachment.

Case Binding (Hardcover)

A rigid cover protects the book from bending, moisture, and long-term wear, making it ideal for collectors’ editions or library use.

How Does Finishing Increasingly Influence Reader Purchase Behavior?

Novel buyers often make decisions within seconds. Finishing elevates appeal:

-

Foil stamping highlights titles and author names.

-

Embossing/debossing adds tactile interest.

-

Spot UV coating draws attention to key design areas.

-

Soft-touch lamination improves perceived luxury.

As consumer behavior shifts toward sensory engagement, finishing plays a critical role in product differentiation.

How Are Market Trends Shaping the Future of Novel Book Printing?

The novel printing industry is undergoing transformation driven by demand for sustainability, personalization, supply-chain flexibility, and global distribution.

How Is Sustainable Printing Becoming a Core Requirement?

Readers and publishers increasingly prefer:

-

FSC-certified paper

-

Soy-based and eco-friendly inks

-

Recyclable packaging

-

Energy-efficient production processes

Manufacturers focusing on sustainability benefit from improved compliance, global export compatibility, and brand reputation.

How Do Digital Printing Technologies Support Small and On-Demand Runs?

Digital printing provides:

-

Cost-effective small-batch production

-

Personalization options (names, limited editions, custom covers)

-

Faster turnaround times for new authors

-

Flexible updates for reprints

For publishers testing new markets, digital printing minimizes financial risks.

How Are Automation and AI-Driven Production Optimizing Efficiency?

Industry automation improves:

-

Color accuracy

-

Production scheduling

-

Waste reduction

-

Reprint consistency

Automated inspection systems detect micro-level defects, ensuring consistent quality for every batch.

How Is Global Distribution Changing Printing Requirements?

With e-commerce driving cross-border book sales, publishers now require:

-

Reliable bulk shipping

-

Durable packaging

-

Consistent quality across international orders

-

Cost-efficient global production planning

Suppliers capable of large-scale export provide a competitive edge in the international marketplace.

Frequently Asked Questions About Novel Book Printing

Q1: How long does it take to produce a batch of printed novels?

A: Production time depends on quantity, materials, and finishing options. Standard softcover novels typically require 7–15 business days for printing, trimming, and binding. Hardcover editions may require 10–20 days due to casing-in and drying time. Large-volume orders or customized finishing such as foil stamping may extend production times slightly, but efficient manufacturers streamline workflows to meet tight publishing schedules.

Q2: How to choose the right paper weight for novel printing?

A: Paper weight selection depends on target audience, budget, and readability preferences. Lighter weights such as 70gsm are ideal for long novels to reduce thickness and shipping cost. Heavier weights like 80–100gsm improve opacity, making them suitable for premium editions or novels with detailed illustrations. The best approach is to balance aesthetics, durability, and production economy based on distribution goals.

How Can Sunnywell Support Professional Novel Book Printing Needs?

High-quality novel book printing requires more than machinery—it requires technical knowledge, material expertise, and a precise production workflow. From paper selection and color calibration to binding craftsmanship and finishing technologies, every element contributes to the reader’s overall experience and the publisher’s market success.

As demand grows for sustainable materials, advanced printing accuracy, and globally competitive manufacturing, businesses need a printing partner that combines reliability with innovation. Sunnywell provides professional novel book printing services with accurate color management, durable binding, high-quality finishing, and export-ready production systems. For brands, authors, and publishers who seek long-term printing support, Sunnywell offers customized solutions that align with quality expectations and market trends.

If professional consultation or customized printing support is required, contact us for detailed guidance and tailored production options.